Explore the complexities of the aircraft parts supply chain in Europe, including key players, regulatory challenges, and future trends. Learn how to ensure reliability and navigate the logistics of aviation components trading and aircraft maintenance parts.

Introduction

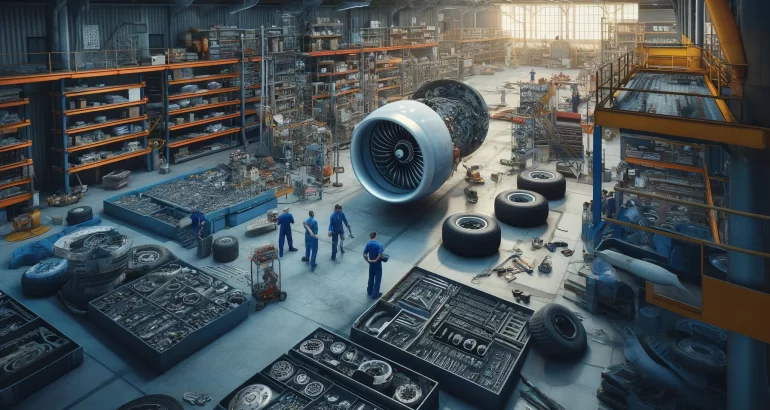

The aircraft parts supply chain in Europe is a critical network that supports the aviation industry by ensuring the timely availability of essential components. This network’s efficiency and reliability are paramount for maintaining the industry’s safety standards and operational effectiveness. This article delves into the complexities of the aircraft parts supply chain, exploring the roles of key players, the challenges they face, and the emerging trends that will shape the future of this sector. By understanding these elements, stakeholders can better navigate the logistics and reliability aspects essential for sustaining the aviation industry.

FAQs

- Why is the aircraft parts supply chain crucial for the aviation industry?

The aircraft parts supply chain ensures the availability of essential components needed for aircraft maintenance and repair. A reliable supply chain maintains safety standards and operational efficiency, which are critical for the aviation industry’s success. - What are the primary objectives of understanding the aircraft parts supply chain?

The primary objectives are to ensure a steady supply of high-quality parts, manage regulatory compliance, and address challenges that could disrupt the supply chain. Understanding these elements helps stakeholders navigate logistics and maintain industry standards. - How does the European aircraft parts supply chain differ from other regions?

The European supply chain is characterized by stringent regulatory standards set by the European Union Aviation Safety Agency (EASA), a diverse network of suppliers and distributors, and a strong emphasis on innovation and sustainability.

The Complexity of the Aircraft Parts Supply Chain

The aircraft parts supply chain is inherently complex due to the variety of components involved, stringent regulatory requirements, and intricate logistical processes. Each of these elements contributes to the overall challenge of ensuring that all necessary parts are available when and where they are needed.

Regulatory Compliance and Certification

Regulatory compliance is a cornerstone of the aircraft parts supply chain. Aviation authorities such as the European Union Aviation Safety Agency (EASA) impose stringent standards that every part must meet. This ensures that all components are airworthy and safe for use. The certification process involves rigorous testing and documentation to verify that parts adhere to these standards. Suppliers and distributors must meticulously follow these regulations to maintain the integrity of the supply chain. Any lapse in compliance can lead to severe consequences, including grounding of aircraft and hefty fines, which underscores the importance of adhering to these stringent requirements.

Diversity of Aircraft Components

Aircraft maintenance requires a wide range of components, each with its own specific role in ensuring the safety and functionality of the aircraft. This diversity complicates inventory management as suppliers need to stock everything from small fasteners to major components like engines and avionics. Managing such a broad inventory requires sophisticated strategies to predict demand accurately and ensure that both common and rare parts are available as needed. This includes leveraging advanced inventory management systems and adopting just-in-time (JIT) practices to minimize overstocking and reduce holding costs while ensuring critical parts are always available.

FAQs

- What makes the aircraft parts supply chain complex?

The complexity arises from the diversity of parts required, stringent regulatory requirements, and intricate logistical processes. Each component must meet specific standards, making inventory management and supply logistics challenging. - How do regulatory requirements impact the supply chain?

Regulatory requirements ensure that all parts are airworthy and safe for use. Compliance involves rigorous testing and certification, which can be time-consuming and costly but is essential for maintaining safety and reliability. - What strategies can be used to manage the diversity of aircraft components?

Effective strategies include advanced inventory management systems, just-in-time (JIT) practices, and leveraging technology for accurate demand forecasting. These approaches help ensure that both common and rare parts are available as needed.

Key Players in the European Aircraft Parts Supply Chain

The European aircraft parts supply chain is supported by various key players, including suppliers, distributors, and trading platforms. Each of these entities plays a vital role in ensuring that the supply chain operates smoothly and efficiently.

Aircraft Spare Parts Suppliers

Leading suppliers in Europe, such as Lufthansa Technik and Airbus, are crucial in providing a broad range of parts essential for aircraft maintenance. These suppliers ensure the availability of high-quality, genuine OEM parts, which are vital for maintaining the safety and reliability of aircraft. Their extensive inventories and global distribution networks enable them to meet the demands of both commercial and private aviation sectors, ensuring that maintenance schedules are not disrupted by part shortages.

Aviation Components Trading

The trading of aviation components involves complex logistics and requires a high degree of reliability. Trading platforms and brokers play a significant role in this process by connecting suppliers with buyers and ensuring smooth, efficient transactions. Reliable trading practices are essential for maintaining trust within the industry and ensuring the timely delivery of parts. These platforms also help mitigate risks associated with supply chain disruptions by providing alternative sources and enabling quick responses to changing market conditions.

Aircraft Maintenance Parts Distributors

Distributors act as intermediaries between suppliers and maintenance facilities, playing a crucial role in managing inventories and ensuring timely delivery of parts. Prominent distributors in Europe, such as Aviall and Satair, are known for their extensive networks and efficient distribution systems. They help bridge the gap between manufacturers and end-users, ensuring that parts are available when needed to maintain the operational readiness of aircraft fleets. Their role is especially critical in handling last-minute demands and emergency situations where quick access to parts is crucial.

FAQs

- Who are the major suppliers in the European aircraft parts supply chain?

Major suppliers include Lufthansa Technik, Airbus, and other leading manufacturers and providers of OEM parts. These suppliers play a crucial role in maintaining a steady supply of high-quality components. - What role do trading platforms play in the aviation components market?

Trading platforms and brokers connect suppliers with buyers, ensuring smooth and efficient transactions. They help maintain trust and reliability in the supply chain by facilitating the exchange of parts and mitigating risks. - How do distributors contribute to the supply chain?

Distributors act as intermediaries between suppliers and maintenance facilities, managing inventories and ensuring timely delivery of parts. Prominent distributors like Aviall and Satair ensure that maintenance schedules are not disrupted by part shortages.

Challenges in the Supply Chain

The aircraft parts supply chain faces numerous challenges that can disrupt the flow of components and impact the aviation industry.

Geopolitical and Economic Factors

Political instability and economic fluctuations can significantly affect the supply chain. Geopolitical events, such as trade wars, tariffs, and sanctions, can lead to increased costs and delays in the availability of parts. Economic downturns can also impact the demand for aviation services, which in turn affects the demand for parts. Companies must navigate these challenges by diversifying their supply sources, maintaining flexible supply chains, and staying abreast of geopolitical developments to anticipate and mitigate potential disruptions.

Supply Chain Disruptions

Unforeseen events such as natural disasters, pandemics, and logistical bottlenecks can disrupt the supply chain. The COVID-19 pandemic, for instance, highlighted the vulnerability of global supply chains to such disruptions. Lockdowns, travel restrictions, and reduced manufacturing capacity led to significant delays and shortages of essential parts. To mitigate the impact of these events, companies must implement robust contingency plans and risk management strategies, such as maintaining safety stock, diversifying suppliers, and adopting agile logistics practices.

Technological Advancements and Innovations

Technological advancements present both opportunities and challenges for the supply chain. Innovations such as 3D printing, blockchain, and artificial intelligence can enhance efficiency and traceability. However, these technologies also require significant investment and adaptation. For instance, 3D printing can reduce lead times and enable on-demand production of parts, but it also requires changes in certification processes and quality assurance standards. Similarly, blockchain can improve transparency and reduce fraud, but its implementation involves overcoming technical and regulatory hurdles.

FAQs

- What geopolitical factors can affect the aircraft parts supply chain?

Geopolitical factors such as trade wars, tariffs, sanctions, and political instability can increase costs and cause delays in the availability of parts. Companies must stay informed and adapt to these changes to mitigate their impact. - How can supply chain disruptions be managed?

Managing disruptions involves robust contingency planning and risk management strategies, such as maintaining safety stock, diversifying suppliers, and adopting agile logistics practices. These measures help companies respond quickly to unforeseen events. - What technological advancements are influencing the supply chain?

Innovations such as 3D printing, blockchain, and artificial intelligence enhance efficiency and traceability. While these technologies offer significant benefits, their implementation requires investment and adaptation to new processes.

Ensuring Reliability in the Supply Chain

Maintaining a reliable supply chain is critical for the aviation industry, and several strategies can help achieve this goal.

Quality Control and Assurance

Rigorous quality control measures are essential to ensure the reliability of aircraft parts. This includes thorough inspections, testing, and certification processes to verify that parts meet safety standards. Suppliers and distributors must implement robust quality assurance systems to detect and address any defects or non-compliance issues promptly. This helps prevent potential safety risks and ensures that aircraft remain airworthy and operational.

Inventory Management and Forecasting

Effective inventory management involves using advanced forecasting techniques to predict demand accurately and prevent shortages or overstocking. Technologies such as artificial intelligence and machine learning can enhance forecasting accuracy by analyzing historical data and market trends. This allows companies to maintain optimal inventory levels, reducing costs and ensuring that parts are available when needed. Additionally, implementing just-in-time (JIT) practices can further improve efficiency by aligning inventory levels with actual demand.

Building Strong Supplier Relationships

Strong relationships with suppliers are crucial for ensuring the reliability of the supply chain. This involves establishing clear communication channels, fostering trust, and collaborating on mutual goals. Long-term partnerships with reliable suppliers can lead to better terms, more consistent supply, and enhanced overall efficiency. Building these relationships requires a proactive approach, including regular engagement, joint problem-solving, and shared commitment to quality and performance.

Ensuring Reliability in the Supply Chain

- What are the key elements of quality control in the supply chain?

Key elements include thorough inspections, testing, and certification processes to verify that parts meet safety standards. Implementing robust quality assurance systems helps detect and address defects promptly. - How can inventory management be optimized?

Inventory management can be optimized using advanced forecasting techniques, artificial intelligence, and machine learning to predict demand accurately. Just-in-time (JIT) practices also help align inventory levels with actual demand. - Why are strong supplier relationships important?

Strong supplier relationships foster trust, improve communication, and lead to better terms and more consistent supply. Collaborating closely with suppliers enhances reliability and overall efficiency in the supply chain.

Future Trends in the Aircraft Parts Supply Chain

The aircraft parts supply chain is continually evolving, with several trends poised to shape its future.

Impact of Digitalization and Industry

Digitalization and the Fourth Industrial Revolution are transforming the supply chain landscape. Technologies such as the Internet of Things (IoT), big data analytics, and artificial intelligence are enhancing supply chain visibility, efficiency, and responsiveness. For example, IoT-enabled sensors can provide real-time tracking of parts, while big data analytics can optimize routing and inventory management. These advancements enable predictive maintenance, allowing companies to anticipate and address potential issues before they lead to downtime.

Sustainability and Environmental Considerations

Sustainability is becoming increasingly important in the supply chain. Companies are adopting more environmentally friendly practices to reduce their carbon footprint and comply with regulatory requirements. This includes sourcing sustainable materials, improving energy efficiency, and implementing waste reduction programs. The aviation industry is also exploring the use of alternative fuels and electric aircraft, which could significantly impact the supply chain by reducing reliance on traditional fossil fuels and promoting greener practices.

FAQs

- How is digitalization impacting the supply chain?

Digitalization, through technologies like IoT, big data analytics, and AI, is enhancing supply chain visibility, efficiency, and responsiveness. These advancements enable real-time tracking, predictive maintenance, and more informed decision-making. - What role does sustainability play in the future of the supply chain?

Sustainability is becoming increasingly important, with companies adopting environmentally friendly practices such as reducing waste, improving energy efficiency, and sourcing sustainable materials. This shift is driven by regulatory requirements and customer expectations. - What is the significance of Industry 4.0 in the supply chain?

Industry 4.0 introduces advanced technologies that transform supply chain operations, making them more efficient, transparent, and adaptable. This includes automation, interconnected systems, and data-driven decision-making processes.

Conclusion

The aircraft parts supply chain in Europe is a complex and dynamic system that plays a critical role in the aviation industry’s success. By understanding the intricacies of the supply chain, recognizing the key players, and addressing the challenges, stakeholders can ensure a reliable and efficient flow of parts. Future trends such as digitalization and sustainability will further shape the supply chain, driving innovation and improving overall performance. Maintaining a robust and reliable supply chain is essential for the continued safety and efficiency of the aviation industry, and adopting best practices in quality control, inventory management, and supplier relationships will be key to achieving this goal.