Explore the crucial role of Aircraft tire suppliers in Europe market, including strategic advantages, regulatory standards, and innovative practices shaping the industry. Targeting a specific part that your company intends to sell, with a regional focus. Discover how Europe’s central location, adherence to strict safety regulations, and technological advancements in manufacturing and supply chain management contribute to enhancing the efficiency, reliability, and sustainability of aircraft tire supply.

Introduction

Summary: This section will introduce the significance of aircraft tire suppliers in Europe, highlighting their crucial role in the aviation industry. It will set the context for the discussion on how these suppliers are pivotal for maintaining the health and safety standards of air travel.

The Importance of Strategic Location in Aircraft Parts Distribution

- European Hub Advantage

- Summary: Discuss how Europe’s geographical position and strong logistics network benefit aircraft tire distribution and the overall aviation parts industry.

- Impact of Regional Airports and Hubs

- Summary: Explain how proximity to major European aviation hubs like Frankfurt, Paris, and Heathrow influences the efficiency of parts distribution.

The Role of Certifications and Standards in Aircraft Tire Supply

- Understanding EASA and FAA Regulations

- Summary: Outline the regulatory landscape governing aircraft tires in Europe, focusing on EASA and FAA standards, and how they affect suppliers.

- Quality Assurance in the Supply Chain

- Summary: Delve into the systems and processes that ensure the supply of high-quality, certified aircraft tires, including OEM partnerships.

Navigating the Challenges of Aircraft Tire Supply in Europe

- Logistical Challenges in Parts Distribution

- Summary: Address common logistical hurdles faced by suppliers, such as customs and transportation delays, and propose potential solutions.

- Market Dynamics and Competitive Landscape

- Summary: Explore the competitive environment among European aircraft tire suppliers, including the strategies for maintaining market share against global players.

Technological Advancements and Their Impact on Aircraft Tire Supply

- Innovations in Tire Manufacturing

- Summary: Highlight recent technological developments in aircraft tire manufacturing and how they enhance product reliability and performance.

- Digitalization of Supply Chains

- Summary: Discuss the adoption of digital technologies in the supply chain, from RFID tracking to AI-driven inventory management, and their benefits.

Sustainability Trends Affecting Aircraft Tire Suppliers

- Eco-friendly Practices in Production

- Summary: Examine how suppliers are integrating sustainable practices in tire production, reducing environmental impact.

- Recycling and Reuse of Aircraft Tires

- Summary: Explore the initiatives for recycling and reusing aircraft tires, contributing to sustainability in the aviation industry.

Introduction

Europe’s aviation industry is a cornerstone of its economic infrastructure, supporting not only widespread commercial connectivity but also a robust supply chain for aviation components. Among these components, aircraft tires stand out due to their critical role in ensuring the safety and efficiency of flights. European suppliers of aircraft tires are not just part of a niche market; they are pivotal players in the broader landscape of global aviation safety. This article explores the multifaceted aspects of aircraft tire supply in Europe, from strategic distribution and regulatory adherence to innovations and sustainability efforts that are often overlooked yet vital for informed stakeholders in the industry.

The Importance of Strategic Location in Aircraft Parts Distribution

European Hub Advantage

Europe’s geographical placement between the Americas and Asia makes it an ideal location for logistics and distribution, especially for time-sensitive aviation parts like aircraft tires. Major European cities are not only political and economic centers but also pivotal air transport hubs. This strategic advantage allows for quicker turnaround times in parts distribution, reducing the downtime of aircraft and ensuring that fleets can return to the skies with minimal delay. Suppliers located in or near these hubs can leverage this proximity to enhance their operational efficiency.

Impact of Regional Airports and Hubs

The influence of regional airports and hubs extends beyond mere geography. Airports such as Frankfurt, Paris-Charles de Gaulle, and London Heathrow are not just transit points but are equipped with advanced facilities dedicated to the storage and rapid distribution of aircraft parts. The presence of specialized logistics services and customs handling expertise at these airports facilitates smoother, faster transactions and deliveries across and beyond the continent, thus significantly influencing the efficiency of the aircraft tire supply chain.

FAQs

- Why is Europe considered a strategic location for aircraft parts distribution? Europe’s central geographic position between major global markets, combined with its advanced logistics and transportation infrastructure, makes it ideal for efficient distribution of aircraft parts, including tires, to various parts of the world.

- How do regional airports contribute to the efficiency of aircraft parts distribution? Regional airports in Europe, particularly those with dedicated cargo and logistics facilities, facilitate swift handling, storage, and redistribution of aircraft parts. This minimizes downtime and ensures faster delivery to maintenance facilities and airlines.

- What advantages do suppliers near major European hubs have over others? Suppliers positioned near major hubs benefit from shorter transit times, reduced transportation costs, and quicker customs processing, which altogether enhance their ability to meet urgent demands more effectively.

The Role of Certifications and Standards in Aircraft Tire Supply

Understanding EASA and FAA Regulations

Navigating the regulatory waters is a critical task for aircraft tire suppliers in Europe. Compliance with the European Union Aviation Safety Agency (EASA) and the Federal Aviation Administration (FAA) standards is non-negotiable. These regulations ensure that every tire supplied meets stringent safety and performance criteria, thus maintaining the high safety standards expected in aviation. Suppliers must constantly stay updated with any changes in these regulations to keep their products and processes compliant.

Quality Assurance in the Supply Chain

The path to ensuring the supply of high-quality aircraft tires is complex and layered with numerous checks and balances. From initial design and manufacturing to final delivery, each step follows rigorous quality assurance protocols. Collaborations with genuine OEM (Original Equipment Manufacturer) partners ensure that the tires are not only manufactured to meet exacting standards but are also continually improved upon based on real-world performance data and technological advancements.

FAQs

- What are the key regulatory bodies governing aircraft tire supply in Europe? The key regulatory bodies are the European Union Aviation Safety Agency (EASA) and the Federal Aviation Administration (FAA), which set comprehensive safety and performance standards for aircraft tires to ensure they meet specific quality criteria.

- How do certifications affect aircraft tire suppliers? Certifications ensure suppliers meet legal and safety requirements, which not only protects the end users but also enhances the supplier’s credibility and marketability in a highly regulated industry.

- Why is quality assurance critical in the aircraft tire supply chain? Quality assurance processes are vital to prevent failures that could lead to severe accidents, ensuring every tire sold meets the highest standards of safety and performance as mandated by regulatory authorities.

Navigating the Challenges of Aircraft Tire Supply in Europe

Logistical Challenges in Parts Distribution

Despite the strategic advantages, suppliers often face logistical challenges such as customs delays and transportation inefficiencies that can impede timely distribution. Tackling these challenges requires a blend of proactive logistics planning, investment in advanced tracking systems, and sometimes, partnerships with local entities to smooth over the bureaucratic hurdles.

Market Dynamics and Competitive Landscape

The aircraft tire supply market in Europe is fiercely competitive, with numerous players vying for a share of the pie. Suppliers must navigate a landscape where pricing, product quality, and service delivery must all be aligned with client expectations. Staying competitive often means investing in research and development to improve product offerings or refining distribution strategies to enhance service speed and reliability.

Technological Advancements and Their Impact on Aircraft Tire Supply

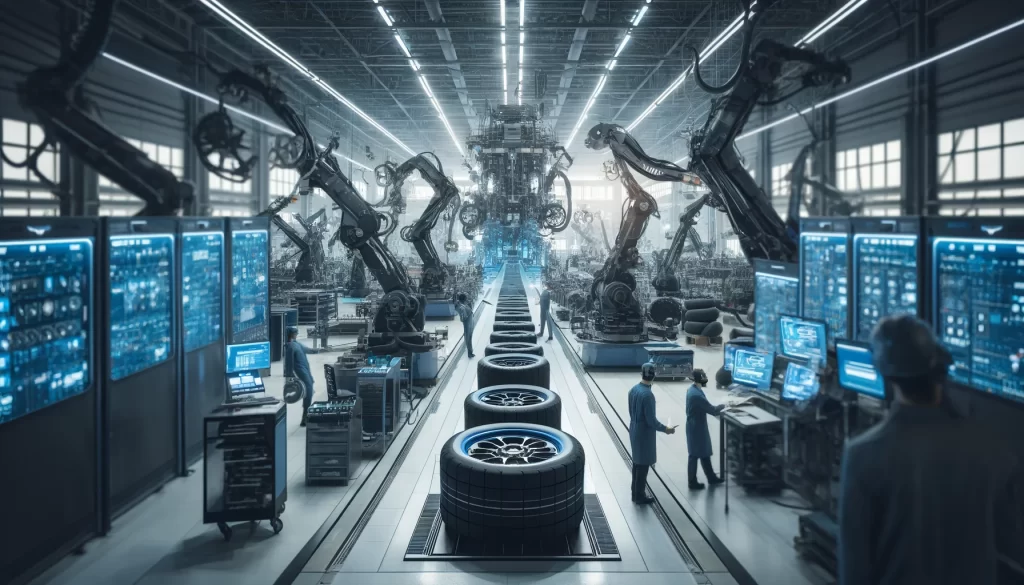

Innovations in Tire Manufacturing

Recent years have seen significant innovations in aircraft tire manufacturing. New materials such as improved rubber composites offer better wear resistance and enhanced performance under extreme conditions. Additionally, manufacturing processes have become more sophisticated, incorporating precision engineering to reduce variances and increase the reliability of the tires.

Digitalization of Supply Chains

Digital technologies are revolutionizing the supply chains of aircraft tire suppliers. Implementations of RFID (Radio-Frequency Identification) for inventory tracking and AI-driven predictive analytics for demand forecasting are enhancing the efficiency of the supply chain, reducing wastage, and ensuring that stocks are aligned with actual market needs, thus reducing overhead costs and improving service delivery.

Sustainability Trends Affecting Aircraft Tire Suppliers

Eco-friendly Practices in Production

Sustainability is becoming increasingly important in aircraft tire production. Suppliers are adopting more eco-friendly manufacturing practices, reducing solvent use, and decreasing the carbon footprint of their production lines. This shift not only responds to regulatory pressures but also aligns with a growing demand from consumers for greener products.

Recycling and Reuse of Aircraft Tires

The end of life for aircraft tires does not mean the end of utility. Recycling and reusing tire materials for different applications is an expanding practice that contributes to environmental sustainability. This includes using recycled tire material in everything from playground surfaces to new tire production, providing a circular economy model that benefits both suppliers and the environment.

FAQs

- What recent technological innovations have impacted aircraft tire manufacturing? Innovations include the development of new rubber composites that offer better durability and performance, and the use of precision engineering to enhance manufacturing consistency and tire reliability.

- How is digitalization improving aircraft tire supply chains? Digital tools like RFID and AI-driven analytics help streamline inventory management, improve forecasting accuracy, and reduce lead times, thereby optimizing the supply chain and reducing costs.

- What benefits do these technological advancements offer to the aviation industry? These advancements lead to the production of higher-quality tires, improved supply chain efficiency, and reduced operational costs, enhancing overall airline safety and profitability.

Conclusion

The aircraft tire supply sector in Europe is marked by a dynamic interplay of strategic advantages, regulatory requirements, and innovative practices that set the stage for a resilient and efficient market. As European suppliers navigate these complex waters, they not only contribute to

the safety and reliability of the aviation industry but also to its ongoing evolution towards more sustainable and technologically advanced operations. Understanding these deeper dynamics provides stakeholders with the insights necessary for making informed decisions in a competitive market.