Explore the critical role of European aviation parts certification, its impact on safety and reliability, and how suppliers can navigate the certification process to gain market access and trust. Learn about key certification bodies, the process, and successful case studies in the aviation industry.

Introduction

In the world of aviation, the integrity and reliability of every component are paramount. The stakes are incredibly high, with the safety of countless passengers and crew members hinging on the proper functioning of aircraft parts. Among these components, airplane tires and main parts hold a critical position, and their certification ensures that they meet rigorous standards. This article delves into the importance of European aviation parts certification, a crucial aspect for buyers and suppliers alike, aiming to shed light on the often-overlooked facets of this vital process.

The Importance of Certification in European Aviation Parts

Certification in aviation parts is not merely a formality; it is a cornerstone of safety and reliability. The aviation industry operates under stringent regulations, and certification ensures that every part, from the smallest bolt to the largest tire, meets these high standards.

Ensuring Safety and Reliability

Certification processes are designed to guarantee that aviation parts are safe and reliable. These processes involve rigorous testing and validation to ensure that each part can withstand the demanding conditions of flight. For example, airplane tires must endure extreme temperatures, high pressure, and rapid changes in altitude. Certification verifies that these tires can perform consistently under such conditions, thereby ensuring the safety of the aircraft and its passengers.

Regulatory Compliance

Regulatory compliance is another critical aspect of certification. The aviation industry is governed by numerous regulations that vary by region and country. Certification ensures that parts comply with these regulations, which is essential for legal operation and market access. Without proper certification, aircraft parts cannot be legally used or sold, which would severely limit the operations of suppliers and manufacturers.

FAQs

- Q1: What are the key benefits of certification for aviation parts? A1: Key benefits include enhanced safety, regulatory compliance, increased reliability, and market trust.

- Q2: How does certification contribute to regulatory compliance? A2: Certification ensures that parts meet regional and international aviation regulations, allowing legal use and sale in the market.

- Q3: Are there specific standards for different types of aviation parts? A3: Yes, different parts have specific standards and testing requirements tailored to their functions and operational environments.

Overview of European Aviation Certification Bodies

Europe is home to several key certification bodies that play a pivotal role in the aviation industry. These organizations ensure that all aviation parts used in European airspace meet stringent safety and quality standards.

EASA (European Union Aviation Safety Agency)

The European Union Aviation Safety Agency (EASA) is the primary body responsible for certifying aviation parts in Europe. EASA sets the standards for safety and quality, and it oversees the certification process for all aviation components. The agency’s rigorous certification protocols ensure that only the highest quality parts are approved for use in aircraft, thus maintaining the overall safety of European aviation.

National Aviation Authorities

In addition to EASA, each European country has its national aviation authority. These authorities work in collaboration with EASA to enforce certification standards and ensure compliance at the national level. For instance, the UK’s Civil Aviation Authority (CAA) and Germany’s Luftfahrt-Bundesamt (LBA) are responsible for overseeing aviation safety and certification within their respective countries. This dual-layer system of regulation and certification helps maintain the highest standards of safety across Europe.

FAQs

- Q1: What is the role of EASA in aviation certification? A1: EASA sets the standards for safety and quality in Europe and oversees the certification process for all aviation components.

- Q2: How do national aviation authorities interact with EASA? A2: National authorities enforce EASA’s standards within their countries and collaborate with EASA to ensure consistent safety and compliance across Europe.

- Q3: Can a part certified by one European authority be used in another European country? A3: Yes, parts certified by EASA or national authorities are recognized across Europe, ensuring interoperability and market access.

The Certification Process for European Aviation Parts

The certification process for aviation parts in Europe is comprehensive and meticulous. It involves several stages, each designed to ensure that every part meets the necessary standards.

Application and Documentation

The first step in the certification process is the application. Suppliers must submit detailed documentation that outlines the specifications and intended use of the part. This documentation includes design plans, material specifications, and test results. The thoroughness of this documentation is crucial, as it forms the basis for the entire certification process.

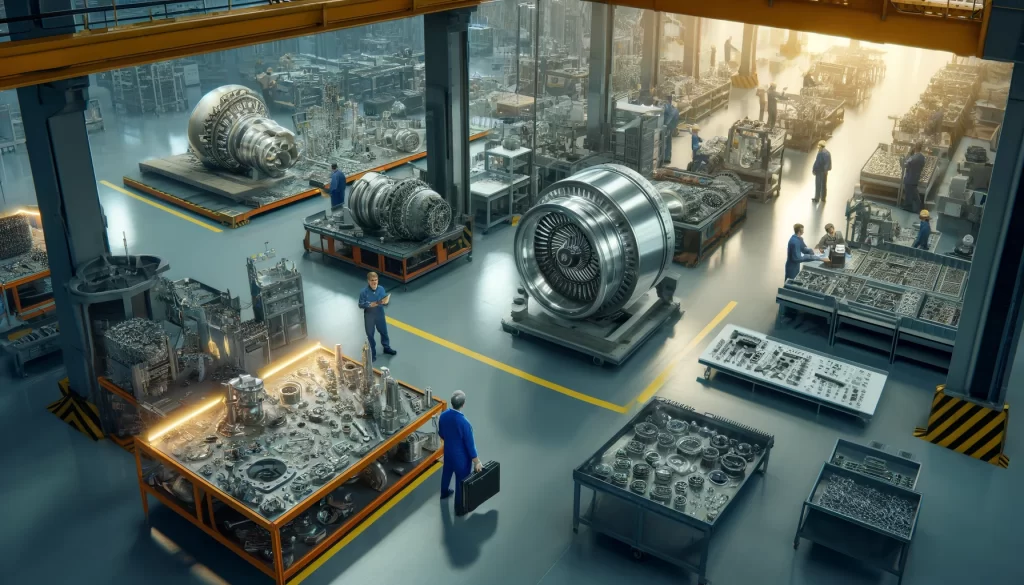

Testing and Quality Assurance in European Aviation Parts

Once the application is submitted, the part undergoes extensive testing and quality assurance. This phase includes both laboratory tests and real-world simulations to evaluate the part’s performance under various conditions. For example, airplane tires are subjected to stress tests that mimic the conditions they will face during takeoff, flight, and landing. These tests ensure that the tires can handle the stresses and strains of actual use.

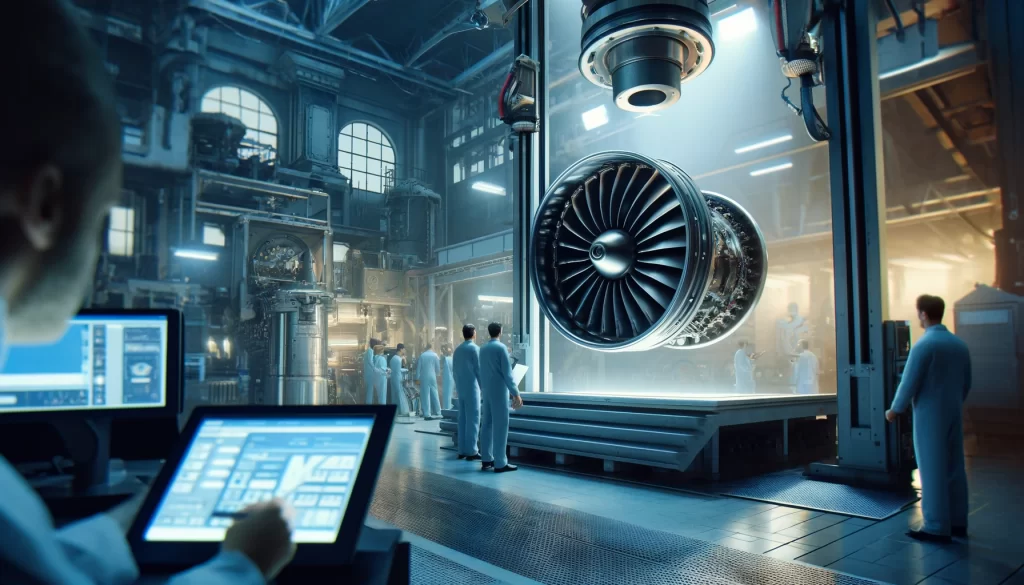

Final Approval and Certification

The final stage of the certification process is the approval phase. After the part has passed all tests and quality checks, it undergoes a final inspection by the certification body. This inspection verifies that the part meets all regulatory and safety standards. Once approved, the part is officially certified and can be used in aircraft operating within Europe.

FAQs

- Q1: What documentation is required for the certification application? A1: Documentation includes design plans, material specifications, test results, and detailed descriptions of the part’s intended use.

- Q2: What types of tests are involved in the certification process? A2: Tests include laboratory tests, stress tests, real-world simulations, and quality assurance checks to ensure parts can perform under operational conditions.

- Q3: How long does the certification process typically take? A3: The duration varies depending on the part’s complexity and regulatory requirements, but it generally takes several months to over a year.

The Impact of Certification on Aircraft Spare Parts Suppliers

Certification has a profound impact on suppliers of aircraft spare parts. It affects every aspect of their operations, from manufacturing to marketing.

Market Access and Trust

Certification opens doors to new markets and builds trust with customers. Certified parts are recognized as meeting the highest standards of safety and quality, which gives customers confidence in their purchase. This trust is crucial in the aviation industry, where the reliability of parts can mean the difference between a safe flight and a disaster. Suppliers with certified parts can access a broader market and attract more customers.

Competitive Advantage in European Aviation Parts

Certified parts provide a significant competitive advantage in the aviation components trading market. Suppliers who offer certified parts stand out from their competitors, as certification is a mark of quality and reliability. This distinction can be a deciding factor for buyers when choosing between different suppliers. Furthermore, certification can lead to long-term contracts and partnerships, as airlines and maintenance companies prefer to work with suppliers who provide certified, high-quality parts.

FAQs

- Q1: How does certification affect a supplier’s market access? A1: Certification allows suppliers to access new markets and build trust with customers, as certified parts are recognized for their quality and reliability.

- Q2: What competitive advantages do certified parts offer suppliers? A2: Certified parts provide a mark of quality that distinguishes suppliers from competitors and can lead to long-term contracts and partnerships.

- Q3: Can certification lead to increased sales for suppliers? A3: Yes, certification enhances a supplier’s reputation, attracts more customers, and can result in increased sales and market expansion.

Challenges and Opportunities in the Certification Process

While the certification process is essential, it is not without its challenges. However, these challenges also present opportunities for growth and improvement.

Common Challenges

One of the most common challenges in the certification process is the complexity of regulatory requirements. Navigating these regulations can be time-consuming and costly, especially for smaller suppliers. Additionally, the rigorous testing and documentation required for certification can be a significant burden. Suppliers must invest in quality assurance and testing facilities, which can be a substantial financial commitment.

Opportunities for Growth

Despite these challenges, the certification process presents numerous opportunities for growth. Successfully navigating the certification process can enhance a supplier’s reputation and credibility. It also opens up new markets and customer bases. Furthermore, the process of certification encourages continuous improvement in quality and safety standards, which can lead to innovations and advancements in aviation technology.

FAQs

- Q1: What are the main challenges suppliers face in the certification process? A1: Challenges include navigating complex regulatory requirements, the high costs of testing and documentation, and the need for extensive quality assurance.

- Q2: How can suppliers overcome these challenges? A2: Suppliers can invest in quality assurance infrastructure, stay updated on regulatory changes, and collaborate with certification bodies for guidance.

- Q3: What opportunities does the certification process present? A3: Opportunities include market expansion, enhanced reputation, continuous improvement in product quality, and potential for innovation.

Conclusion

Certification in the aviation parts industry is indispensable. It ensures that every part, whether it is an airplane tire or a maintenance component, meets the highest standards of safety and reliability. For suppliers, certification opens up new markets, builds trust with customers, and provides a competitive edge. Despite the challenges, the opportunities presented by the certification process are significant. By focusing on certification, suppliers can improve their products, enhance their reputation, and drive business growth. The importance of certification cannot be overstated, and its benefits extend to all stakeholders in the aviation industry.