The aviation industry operates under strict safety standards and considers every aspect of aircraft maintenance and repair, and this strictness is critical to ensuring the safety of passengers and crew, we will talk about Importance of Genuine OEM Aircraft Parts .

One of the strictest standards in aircraft maintenance is using OEM parts. It should be known that in flying and soaring in the sky, safety is not a choice, but a factor of trust. In this complex system, every screw and every sensor creates a connection that establishes trust and harmony between aircraft and human life.

In the following, you will understand that original aircraft OEM parts are specifically designed and manufactured by the aircraft manufacturer or its authorized partners, and in this article, meemsdxb will guide you on the importance of original aircraft OEM parts, how to distinguish them from counterfeit or aftermarket parts, and the risks associated with their use.

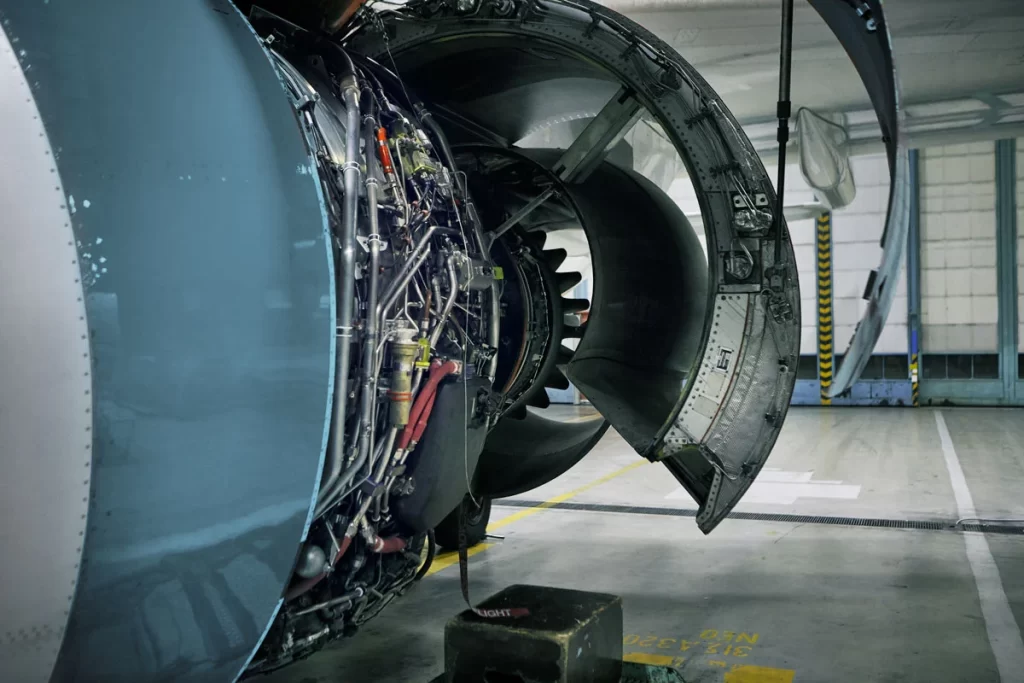

The Importance of Genuine OEM Aircraft Parts

When it comes to aircraft maintenance, original OEM parts are always the first choice for several important reasons.

The reason for choosing original OEM aircraft parts is that these parts are designed and manufactured to the exact specifications of the aircraft manufacturer, ensuring optimal performance and compatibility.

We should also add that to meet industry standards and ensure their reliability and safety, OEM parts undergo rigorous testing and certification processes. Ensuring safety means a flawless flight that saves the lives of hundreds of passengers and gives them peace of mind. Let’s take a closer look:

Enhancing Safety and Reliability

The use of original OEM parts is of the highest degree in providing and maintaining a safety level. And they always have the top priority in the aviation industry.

OEMs invest significant resources in research to ensure that their parts meet exacting quality standards.

• Development of parts.

• Testing parts regularly.

Original OEM parts, by investing in these two items, can easily minimize the risk of component failure or failure that could compromise the overall safety of the aircraft and its occupants.

Regulatory Compliance of Genuine OEM Aircraft Parts

Aviation authorities and regulatory bodies around the world require strict compliance with industry regulations.

Original OEM parts are specifically engineered to meet these exacting regulatory requirements, which include performance, durability, and reliability standards.

One caveat is that using non-OEM parts may result in non-compliance, potentially resulting in:

• Legal consequences

• Plane landing

• Loss of certificate

Optimum Performance

The performance of an aircraft is directly affected by the reliability of its components as well. Original OEM parts are designed to work well with other aircraft systems and ensure optimum performance for the aircraft.

These components undergo extensive testing to verify their performance under various real-world operating conditions. With OEM aircraft parts, you can be sure that they will meet or even exceed the aircraft manufacturer’s specifications.

Differentiating Genuine OEM Parts from Counterfeit or Aftermarket Parts

One of the challenges in the aviation industry is the existence of counterfeit non-OEM parts that try to imitate original OEM parts. Imitations that lack the rigorous testing and safety design that true OEM parts define.

Therefore, I highly recommend distinguishing between these alternatives and understanding the associated risks.

Quality Assurance and Traceability of Genuine OEM Aircraft Parts

Genuine OEM parts come with a high level of quality assurance. Unique qualities that

OEM offers include the following:

• OEMs have strict quality control processes to ensure that every part meets the required standards.

• OEMs are traceable, meaning their origin and date of manufacture can be verified.

• Counterfeit and non-OEM parts are easy options to eliminate! Because of the lack of the same level of quality assurance and traceability, they pose a significant risk to the safety and reliability of the aircraft.

Manufacturer Support and Warranty

When purchasing original OEM parts, customers can benefit from manufacturer support and warranty coverage.

This assurance guarantees the quality and reliability of OEM parts.

Any defects or problems are quickly resolved. You can also manage heavy expenses!

In contrast, counterfeit or aftermarket parts lack manufacturer support and warranty coverage, leaving operators vulnerable to additional costs and risks.

Compatibility and Fitment

Original OEM parts are specifically designed to fit into aircraft systems and be compatible with other parts. This compatibility comes from the fact that these parts undergo extensive testing to minimize the risk of installation errors or performance problems.

Counterfeit parts are designed without considering tests. It is easy to say that they do not provide compatibility with parts and potentially lead to operational problems and increased maintenance needs.

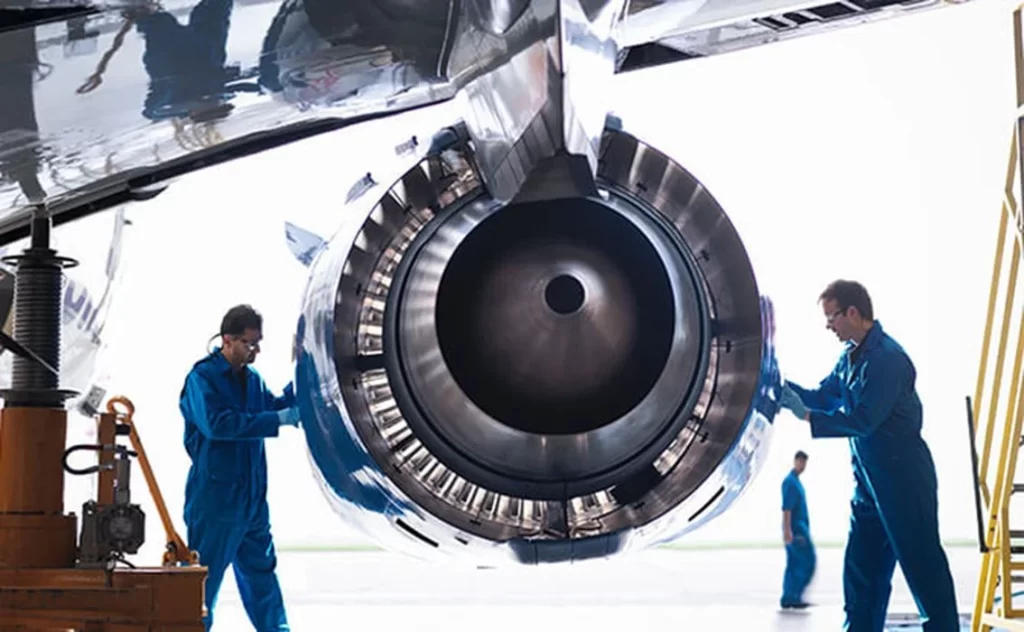

The Role of OEMs in the Aviation Industry

OEMs play a vital role in the aviation industry beyond manufacturing aircraft. This includes their expertise and involvement in the design, engineering, testing, and continuous improvement of aircraft components.

By understanding the role of OEMs, you can be potentially effective in aircraft maintenance.

Design and Engineering Expertise

A lot is invested in the design and engineering expertise of OEMs so that every part is optimized for performance, reliability, and safety. By using genuine OEM parts, aircraft operators can take advantage of the OEM’s collective knowledge and experience and improve overall performance.

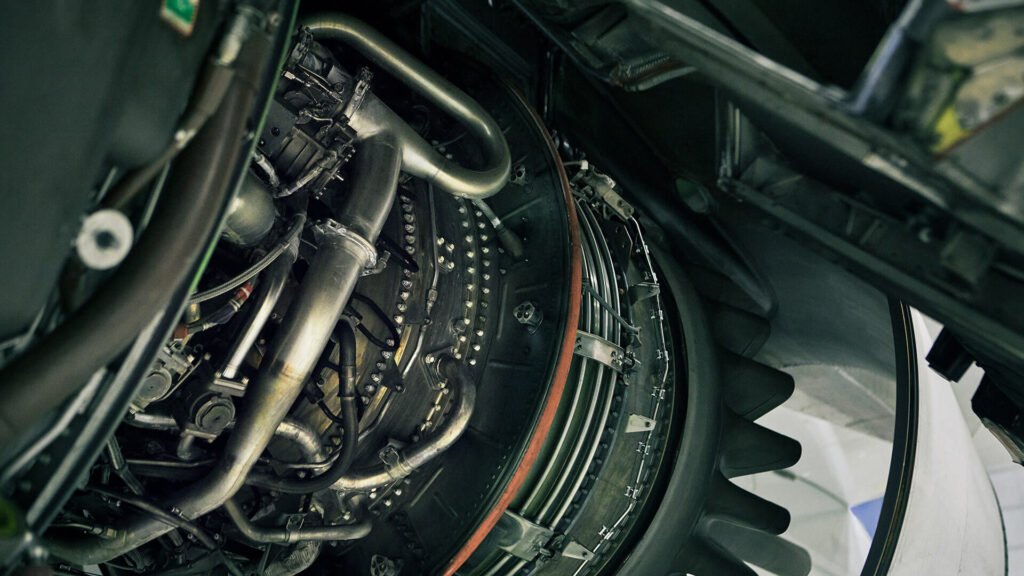

Rigorous Testing and Certification

By choosing original OEM parts, operators can be sure of the proven performance of these parts. Find the cause in the following cases:

• OEMs put their parts through rigorous testing and certification processes.

• Strictly conform to industry standards.

• Experiments are simulated in operational conditions.

• They confirm the durability and reliability of the parts.

Continuous Improvement and Innovation

While not perfect, OEMs are continuously striving to improve their products and incorporate the latest technological and material advances. And this growth is commendable.

The Risks of Using Non-OEM Parts

While original OEM parts have many advantages, using non-OEM parts carries significant risks that should not be ignored to ensure a safe ride.

Compromised Safety and Reliability

These fake parts are not tested, and this issue jeopardizes safety and reliability.

Legal and Regulatory Consequences

Aviation authorities need to comply with certain regulations and standards, and the use of unauthorized parts leads to these two cases:

• Heavy fines

• Airplane grounding

Negative Impact on Aircraft Value

Using non-OEM parts can hurt the value of the aircraft.

Ensuring Authenticity and Verification Processes and Certifications

Various verification and certification processes are available to reduce the risks associated with counterfeit or non-OEM parts. These things help a lot to ensure the authenticity of the parts:

• Working with OEM-authorized distributors and dealers is one way to verify the authenticity of OEM parts.

• Part number verification is a critical step in ensuring the authenticity of OEM parts.

• Independent inspection and testing services verify OEM parts.

Choosing the Right Supplier for Genuine OEM Parts

Choosing the right supplier for original OEM parts is critical to ensuring the originality, quality, and availability of these parts. Let’s find the right supplier together with meemsdxb:

• Trusted suppliers have a proven track record of being able to supply original OEM parts maintain high-quality standards. And so far, they have achieved good customer satisfaction.

• An ideal supplier should cover a wide range of aircraft types and models. Comprehensive stock of original OEM parts is considered a very good advantage.

• A reliable supplier should be able to provide the following for specific needs:

Quick answers.

Technical expertise.

Help in identifying the right parts.

FAQs:

Q: What are OEM parts?

A: OEM stands for Original Equipment Manufacturer. OEM parts are parts that are designed and manufactured by the same company that manufactures the original equipment. And then they are sold of high quality.

Q: Why is it important to use genuine OEM parts in aircraft maintenance?

A: Original OEM parts are specifically designed and tested to meet industry standards and ensure:

• Reliability performance

• Optimal safety

You should know that by using non-OEM or fake parts, you are endangering the health of the aircraft, and this means the loss of the safety of each part in a chain.

Q: How can I verify the authenticity of OEM parts?

A: Verification processes include the following:

• Provision of parts from authorized distributors.

• Verification of part numbers and documents.

• Use of inspection services.

• Independent testing.

Q: Are OEM parts more expensive than non-OEM alternatives?

A: Yes, OEM parts may have a higher initial cost than non-OEM alternatives. This issue cannot be ignored.

But you should know that these parts save long-term costs by minimizing the following:

• Risk of component failure

• Maintenance costs

Q: Can I use non-OEM parts if they are cheaper?

A: The use of non-OEM parts poses significant risks to aircraft safety and reliability and may result in legal and regulatory consequences. This issue cannot be ignored or called unimportant. Well, as an informed person, it’s important to consider the long-term consequences and potential costs before using non-OEM parts.

Conclusion

Genuine OEM parts to ensure safety, optimal performance, and reliability in the aviation industry. You also find that these parts may have a higher price tag. But really, they should be considered an investment, not an expense!

You should know that there are fake, non-OEM parts that show up in safety clothing. They are whispers of doubt and creating disharmony that can upset the delicate balance of the heavens.

While it may cost more, the long-term value and cost savings associated with original OEM parts outweigh the risks of using non-OEM parts. By choosing the right supplier and using verification processes, operators can source and install genuine OEM parts and protect the integrity and performance of their aircraft.

Finally, you should know that choosing original OEM parts is not just about cost. Rather, it is about being responsible, and that means respecting the lives entrusted to you.

Sources

Aircraft Parts & Supplies

Federal Aviation Administration (FAA) Parts Manufacturer Approval (PMA)

International Aviation Club

Air Transport Safety Bureau (ATSB) Report on Counterfeit Parts

European Aviation Safety Agency (EASA) Counterfeit Parts Information

The Aviation Industry’s War on Counterfeit Parts

2 thoughts on “Genuine OEM Aircraft Parts”