Flying in the infinite skies and ensuring the safe journey of hundreds of passengers depends on the performance of every single component, from the smallest sensor to the gigantic engine.

Success is achieved with Reliable Aerospace Components. Meemsdxb is with you to explore the wonderful world of reliable aerospace components. Trust, travel and uncover the secrets behind their unwavering performance together.

And we will have an article to the resistance that aerospace parts show in the most difficult conditions, such as in extreme heat, the bone-forming vacuum of space, and the relentless vibrations of a long journey. Be with us.

What Do Reliable Components Mean in Aerospace?

To understand reliable aerospace components, think of the overall relationship between the fuselage and its target components.

In fact, it is an unwavering guarantee that every part will perform exactly as intended, every time, flawlessly, under the most extreme conditions. It’s the difference between a successful and growing position and a fiery warning position.

Functionally Reliable

We understand the correct functional reliability in this way that each component performs its assigned task flawlessly or not! Now, this task can be in the production of thrust force, data transmission or maintaining structural integrity.

Otherwise, it is impossible to imagine a chariot without these items and its correct operation and the consequences that follow.

Durable and Robust

From burning deserts to subzero stratospheres, reliable aerospace components must withstand a wide range of environmental assaults. Think of them as seasoned warriors who weather the toughest storms and still remain strong.

Resistant to Wear and Tear

Continuous operation has specific complications related to each part, so parts must be built to last. In this way, every department needs endurance to overcome fatigue and failure.

Tolerant to Manufacturing Defects

Even the most precise processes can have minor flaws. This is where Tolerant to Manufacturing Defects should be considered. Reliable components can compensate for these and ensure smooth operation despite microscopic imperfections. In essence, this is an unyielding necessity.

The Components That Are Considered Reliable

Aerospace components are very important and basic components that cause reliability in the parts. Here are the key components that make up a reliable aerospace component:

Material Mastery

Each part is a testament to the careful selection of materials. These items are selected from high-strength alloys to advanced composites, or any material that is subjected to specific stresses for their specific performance, but on a very high and huge scale. All items must have Material Mastery as a principle.

Precise Engineering

In this industry, design plays an important role. Every dimension, every curve, every weld and cut is carefully calculated to ensure optimal performance and stress distribution. They are very regular, carefully engineered.

State-of-the-Art Manufacturing

From advanced machining techniques to strict quality control measures, every step of the manufacturing process is carried out to the highest standards.

There are very complex and strict standards that to reject them, you have to show yourself perfect and excellent in every detail well and with 100% power.

Rigorous Testing and Certification

Before the plane flies in the sky, the parts are subjected to a series of difficult tests to experience different and difficult aerospace situations before flying and then enter the boundless sky.

Continued Maintenance and Monitoring

Even the most reliable parts need TLC. Ongoing maintenance and monitoring is required to maintain peak condition:

Regular inspections

Preventive Maintenance

Data-driven monitoring

Exploring Different Types of Reliable Components

The world of aerospace components is very large and diverse. In this long list of Reliable Components, let’s take a look at the most powerful ones. In-flight items can take over a larger portion of reliable flight duties.

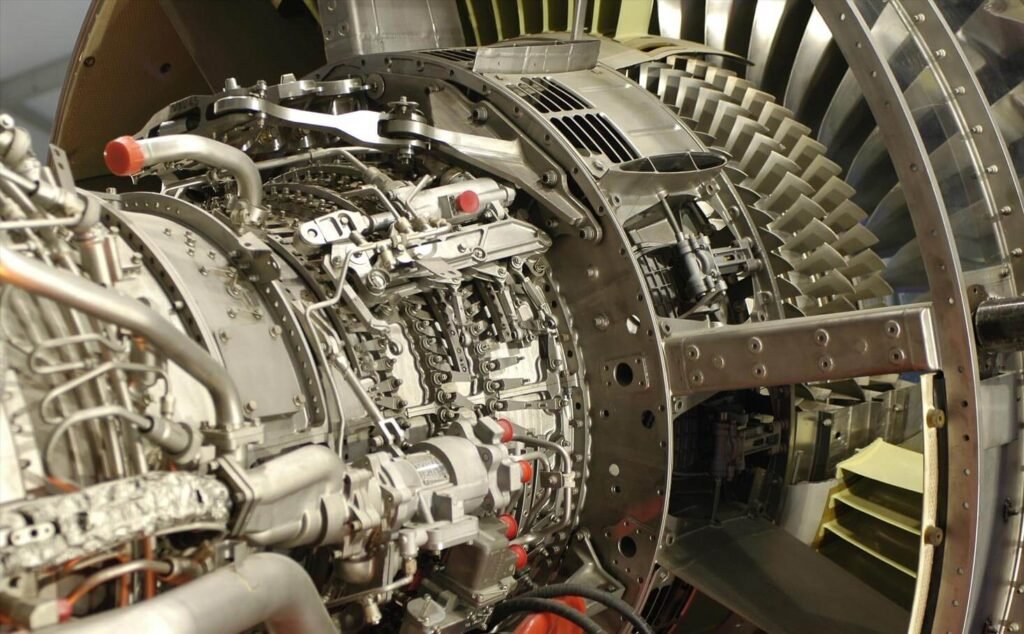

Engines

The beating heart and main power center on these large air decks are engines. These engineering marvels are built to withstand the unimaginable heat and pressure that the aircraft endures.

From the majestic turbofans of commercial jets to the sleek rocket engines that propel us into the sky, each is a testament to the pursuit of ultimate certainty.

Landing Gear

The landing gear is a sturdy steel base that withstands the immense downward pressure at hundreds of kilometers per hour, thus ensuring a smooth and safe transition from the sky to the ground. In fact, Landing Gears are the unshakable reliability of any landing.

Life Support Systems

Life support systems make the environment of the aircraft safe by providing clean air, regulated pressure and comfortable temperature, thus supporting the passengers and crew.

Navigation Systems

Advanced navigation systems, using an array of technologies from GPS to inertial sensors, provide the aircraft in the sky with the following:

Carefully draw the path ahead.

Providing a guarantee of the reliability of the unshakability of each component.

The Growth of Endless Progress in Reliable Aerospace Components

Growth and ascent in a future based on reliability is still there, and there are still many paths to take on this never-ending path. It can be easily said that the search for reliable aerospace components is not a stagnant thing, and it is a path that is constantly evolving.

Hypersonic Speeds

New materials that can withstand extreme heat, innovative designs that optimize reusability, and intelligent monitoring systems that predict and prevent failures are exciting.

All the features that this item presents are challenges and opportunities that await on the horizon and require more unwavering reliability from our aerospace components. And how good it is to put ourselves in this endless world with a little reflection and cause growth in this industry.

AI and the Future of Component Monitoring

In today’s digital age and growth, artificial intelligence is becoming a game changer in the field of reliable components. By examining the data and using advanced artificial intelligence algorithms, possible failures can be predicted before they occur.

This predictive maintenance is revolutionizing the industry, extending component life, minimizing downtime, and ensuring that every flight is performed at optimum performance.

Collaboration and Progress

In this large and vast industry, searching for reliable components is not enough individual effort.

Growth in this global industry requires collaboration where knowledge is shared, expertise is exchanged, and best practices are adopted across borders and continents.

In fact, this exchange of information and ideas will lead to innovations that will be the key to unlocking a future where reliability is not just a privilege, but a global standard in the sky.

FAQs:

Q: Why is reliability important in aerospace components?

A: Reliability in aerospace parts is very important. And the reason is very clear that, despite failures, we will have very costly consequences, including lives and finances. Therefore, when it comes to the lives of hundreds of passengers, ensuring the safety and performance of the aircraft is very important.

Q: How are aerospace components tested for reliability?

A: Aerospace components are regularly subjected to rigorous testing protocols to ensure their reliability. The following are just a few examples of tests performed on aircraft:

- Non-destructive testing methods

- Simulation

- Stress testing in controlled environments to evaluate the performance of components under extreme conditions

- Defect detection

- Hidden disorders

Q: What advancements have been made in material science for aerospace components?

A: Continuous advances in materials science have played a major role in increasing the reliability of aerospace components. The development of lightweight yet strong materials such as the following has caused them to show better strength, durability and resistance (against wear, fatigue and corrosion) and not be dangerous.

As:

- Carbon composites

- Titanium alloys

Q: How does supply chain management contribute to aerospace component reliability?

A: Supply chain management plays an important role in having the following for you:

- Ensuring reliability in aerospace parts.

- Traceability and transparency throughout the supply chain and help identify potential risks.

- Trust building.

Q: How do aviation authorities enforce reliability standards?

A: Aviation authorities enforce strict regulations such as the following to maintain the highest level of safety in aerospace components.

- Federal Aviation Administration (FAA)

- European Union Aviation Safety Agency (EASA)

- International Civil Aviation Organization (ICAO)

To bypass all regulations, manufacturers must comply with regulations to obtain certificates to demonstrate compliance with safety and quality standards.

Q: Can technology-driven solutions improve aerospace component reliability?

A: Yes, we owe this huge revolution in the field of reliability of aerospace parts to the integration of sensors and real-time monitoring systems. By collecting and analyzing data about part performance, operators can:

- Identify potential failures before they occur.

- Enable proactive maintenance and replacement strategies.

- They optimize the reliability of the part.

- They minimize the risk of unexpected failures.

Q: What are some best practices for ensuring reliability in aerospace components?

A: Best practices to ensure reliability in aerospace parts include the following:

- Focus on materials

- Production processes

- The experiment

- Supply Chain Management

Also, note that implementation of these best practices will maintain the highest standards to ensure reliable aerospace components for the skies and optimize performance.

Conclusion

The path of Reliable Aerospace Components is based on human ingenuity to ensure these great air decks for our travels. These parts, with their large and small sizes, on their single function, cause the safe travel of hundreds of passengers, and it takes a lot of time to reject all these options.

As the industry evolves, it is critical that we keep up with the pace of science and maintain the highest standards to ensure reliable aerospace parts for safer skies.

Resources:

Aerospace Manufacturing and Design

NASA Aerospace Components

Aviation Week

Aerospace Testing International

Society of Aerospace Engineers (SAE)

4 thoughts on “Reliable Aerospace Components”