Explore the intricacies of strategic sourcing for aircraft components, from navigating the complex supply chain to selecting reliable suppliers and embracing technological advancements. This comprehensive guide delves into the challenges and best practices in aircraft parts distribution, ensuring safety and efficiency in the aviation industry.

Introduction

- Overview of Strategic Sourcing in Aviation

- Summary: Discuss the critical role of strategic sourcing in ensuring the availability, reliability, and cost-effectiveness of aircraft components in the aviation industry.

- Importance of Reliable Aerospace Components

- Summary: Highlight the significance of sourcing reliable components for safety, efficiency, and long-term operational sustainability in aviation.

Understanding Aircraft Parts Distribution

- The Aircraft Parts Supply Chain

- Summary: Explain the complexity of the aircraft parts supply chain and the importance of efficient distribution networks.

- Challenges in Aircraft Parts Distribution

- Summary: Identify common challenges in the distribution of aircraft parts, including logistics, quality control, and regulatory compliance.

Sourcing Reliable Aerospace Components

- Criteria for Selecting Aerospace Components Suppliers

- Summary: Outline key criteria for selecting suppliers, such as certification, quality assurance, and track record.

- Technological Advancements in Aerospace Component Manufacturing

- Summary: Discuss how advancements in technology have improved the quality and reliability of aerospace components.

The Role of Online Aircraft Parts Stores

- Benefits of Online Sourcing for Aircraft Parts

- Summary: Explore the advantages of using online platforms for sourcing aircraft parts, including increased accessibility and comparison shopping.

- How to Evaluate Online Aircraft Parts Stores

- Summary: Provide guidelines for evaluating the credibility and reliability of online stores offering airplane spare parts for sale.

Best Practices in Commercial Aviation Spares Procurement

- Strategies for Effective Procurement

- Summary: Share best practices for procuring commercial aviation spares, focusing on cost-efficiency, quality, and supplier relationships.

- Mitigating Risks in Aircraft Parts Procurement

- Summary: Discuss strategies to mitigate risks associated with the procurement of aircraft parts, such as counterfeit parts and supply chain disruptions.

Conclusion

- The Future of Aircraft Components Sourcing

- Summary: Offer insights into the future trends in aircraft components sourcing, including sustainability and digital transformation in the supply chain.

Introduction of Aircraft Components Sourcing

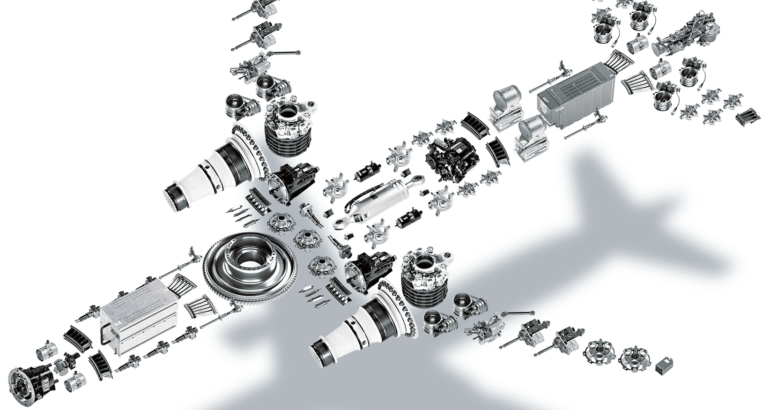

The Critical Role of Strategic Sourcing

Strategic sourcing in aviation transcends the conventional procurement process, embedding itself as a pivotal element in the aviation industry’s quest for operational excellence. This meticulous approach to sourcing aircraft components ensures not only the economic efficiency of airlines and maintenance providers but also, more importantly, the safety and reliability of the aircraft themselves. In an environment where the margin for error is negligible, the strategic sourcing of reliable aerospace components becomes a cornerstone of aviation safety. It involves a deep understanding of the global supply chain, a commitment to quality, and an anticipation of the industry’s evolving needs, ensuring that every part—from the smallest fastener to the most critical engine component—meets the highest standards of reliability and performance.

Ensuring Reliability in Aerospace Components

The importance of sourcing reliable aerospace components cannot be overstated in an industry governed by stringent safety standards and regulatory compliance. Reliable components are the backbone of safe flights and efficient operations, requiring sourcing strategies that prioritize quality, certification, and the supplier’s track record. This focus on reliability extends beyond the procurement of parts; it encompasses a comprehensive vetting process, ensuring that every component contributes positively to the aircraft’s overall performance and safety. By prioritizing reliability in aerospace components, the aviation industry can mitigate risks, reduce operational disruptions, and maintain the highest safety standards.

FAQs

- Why is strategic sourcing important in aviation?

- Strategic sourcing ensures the procurement of high-quality, reliable aircraft components, crucial for safety, efficiency, and cost-effectiveness in aviation operations.

- How does the aviation industry ensure the reliability of aerospace components?

- Through rigorous vetting processes, prioritizing suppliers with strong track records, certifications, and a commitment to quality and safety standards.

- What role do suppliers play in aviation safety?

- Suppliers are integral to aviation safety, providing components that meet strict regulatory standards and contribute to the overall reliability of aircraft.

Understanding Aircraft Components Distribution

Complexity of the Aircraft Parts Supply Chain

The aircraft parts supply chain represents a complex network of manufacturers, distributors, and operators, each playing a crucial role in the availability and distribution of essential components. This complexity is compounded by the global nature of the aviation industry, where parts must be sourced, certified, and delivered across borders with precision and efficiency. The distribution of aircraft parts is a logistical ballet, requiring seamless coordination and a deep understanding of regulatory requirements to ensure that the right part reaches the right place at the right time. This intricate process underscores the importance of strategic partnerships and advanced logistics solutions in overcoming the challenges of aircraft parts distribution.

Challenges in Aircraft Components Distribution

Navigating the challenges of aircraft parts distribution requires a strategic approach to logistics, quality control, and regulatory compliance. These challenges range from managing the logistics of global distribution networks to ensuring the authenticity and certification of parts. The risk of counterfeit parts, coupled with the need for strict adherence to aviation regulations, adds layers of complexity to the distribution process. Effective aircraft parts distribution strategies must address these challenges head-on, employing advanced tracking technologies, rigorous supplier vetting, and comprehensive quality assurance programs to maintain the integrity of the supply chain and ensure the safety and reliability of the aircraft components.

FAQs

- What makes the aircraft parts supply chain complex?

- Its global nature, the need for precision logistics, regulatory compliance, and the coordination required among various stakeholders.

- How are challenges in aircraft parts distribution addressed?

- Through strategic partnerships, advanced logistics, technology for tracking and quality assurance, and rigorous compliance with aviation regulations.

- Why is managing counterfeit parts a challenge in aviation?

- Counterfeit parts pose significant safety risks and regulatory compliance issues, requiring sophisticated detection and quality control measures.

Sourcing Reliable Aircraft Components

Criteria for Selecting Aerospace Components Suppliers

Selecting aerospace components suppliers is a critical decision that impacts the safety, efficiency, and cost-effectiveness of aviation operations. The criteria for this selection process extend beyond price, encompassing factors such as certification, quality control systems, production capabilities, and the supplier’s history of reliability. Suppliers must demonstrate a commitment to the highest standards of quality and safety, with certifications like ISO 9001 and AS9100 serving as benchmarks of excellence. This rigorous selection process ensures that only the most reliable and capable suppliers contribute to the aviation supply chain, supporting the industry’s unwavering commitment to safety and performance.

Technological Advancements in Aerospace Component Manufacturing

Technological advancements have significantly influenced aerospace component manufacturing, introducing new materials, manufacturing processes, and quality control techniques that enhance the performance and reliability of aircraft parts. Innovations such as additive manufacturing (3D printing) and advanced composites are revolutionizing the production of aerospace components, offering improvements in weight, strength, and durability. These advancements not only contribute to the efficiency and safety of aircraft but also open new avenues for the design and production of parts. Embracing these technological innovations is essential for suppliers to remain competitive and for the aviation industry to continue its trajectory toward improved performance and sustainability.

FAQs

- What criteria are important when selecting aerospace components suppliers?

- Key criteria include certifications, quality control systems, reliability, production capabilities, and a proven track record.

- How have technological advancements impacted aerospace component manufacturing?

- They’ve introduced new materials and processes that improve the performance, reliability, and sustainability of aircraft parts.

- Why is embracing technological innovation important for suppliers?

- It ensures competitiveness, meets the evolving needs of the aviation industry, and supports continuous improvement in aircraft performance and safety.

The Role of Online Aircraft Parts Stores

Advantages of Online Aircraft Components Sourcing

The digital transformation of the aviation supply chain has led to the emergence of online aircraft parts stores, revolutionizing how components are sourced and procured. These platforms offer unparalleled access to a global inventory, enabling buyers to easily compare prices, specifications, and supplier reputations. The convenience of online sourcing extends beyond mere accessibility; it introduces a level of transparency and efficiency previously unattainable. Buyers can now make informed decisions quickly, ensuring that their operations remain uninterrupted and cost-effective. This shift towards online procurement is a testament to the industry’s adaptation to technological advancements, meeting the needs of a dynamic and global marketplace.

Evaluating Online Aircraft Parts Stores

While the benefits of online aircraft parts stores are significant, the importance of diligent evaluation cannot be overstated. Buyers must assess the credibility and reliability of these platforms to avoid counterfeit parts and ensure compliance with aviation standards. This involves verifying certifications, reading customer reviews, and understanding the store’s return and warranty policies. Additionally, the ability to provide documentation proving part authenticity and traceability is a crucial factor in the evaluation process. By thoroughly vetting online stores, buyers can leverage the advantages of digital sourcing while safeguarding the integrity of their supply chain and the safety of their operations.

FAQs

- What are the main benefits of using online aircraft parts stores?

- Online stores offer access to a global inventory, competitive pricing, and the ability to easily compare suppliers, enhancing procurement efficiency and transparency.

- How can buyers evaluate the reliability of online aircraft parts stores?

- By verifying certifications, reading customer reviews, checking return policies, and ensuring the store provides part traceability and authenticity documentation.

- What precautions should be taken when purchasing from online aircraft parts stores?

- Buyers should ensure the store is reputable, avoid deals that seem too good to be true, and prioritize stores that offer secure payment methods and robust customer support.

Best Practices in Commercial Aviation Spares Procurement

Effective Procurement Strategies

Procuring commercial aviation spares is a critical task that demands a strategic approach to ensure operational efficiency and cost-effectiveness. Best practices in this area include developing strong relationships with trusted suppliers, implementing rigorous quality assurance processes, and leveraging technology for inventory management. Establishing long-term partnerships with suppliers can lead to better pricing, priority access to critical parts, and improved support services. Moreover, adopting advanced inventory management systems helps in forecasting demand more accurately, reducing the risk of stockouts or excess inventory. These strategies, when effectively implemented, can significantly enhance the procurement process, ensuring that airlines and maintenance providers have access to the spares they need, when they need them.

Mitigating Risks in Aircraft Parts Procurement

The procurement of aircraft parts is fraught with risks, from the potential for counterfeit parts to supply chain disruptions. Mitigating these risks requires a multifaceted approach, including conducting thorough supplier audits, insisting on traceability for all parts, and diversifying the supplier base. Counterfeit parts, which pose a significant safety risk, can be combated through stringent inspection and verification processes. Additionally, building a diversified supplier base can protect against supply chain disruptions, ensuring that alternative sources are available if a primary supplier encounters issues. By proactively addressing these risks, procurement professionals can maintain the integrity of their supply chain and ensure the continuous availability of high-quality aviation spares.

FAQs

- What are some effective procurement strategies for aviation spares?

- Developing long-term supplier relationships, leveraging technology for inventory management, and implementing strict quality assurance processes are key strategies.

- How can risks in aircraft parts procurement be mitigated?

- Through thorough supplier audits, insisting on part traceability, diversifying the supplier base, and employing stringent inspection processes to combat counterfeit parts.

- Why is supplier diversification important in procurement?

- It reduces dependency on a single source, mitigating the risk of supply chain disruptions and ensuring continuous access to necessary parts.

Conclusion

The Future of Aircraft Components Sourcing

The future of aircraft components sourcing is poised for further evolution, driven by technological advancements, sustainability concerns, and the increasing complexity of global supply chains. As the industry moves forward, we can expect a greater emphasis on digital platforms that offer enhanced sourcing capabilities, along with a focus on sustainable and environmentally friendly components. The integration of blockchain technology could also play a significant role in improving traceability and combating counterfeit parts. These developments will require procurement professionals to stay abreast of technological trends and adapt their strategies accordingly, ensuring that their sourcing practices remain effective and aligned with the industry’s future direction.

Shaping the Aviation Industry’s Sourcing Practices

As we look to the future, the strategic sourcing of aircraft components will undoubtedly continue to shape the aviation industry’s operational strategies and economic landscape. The ability to navigate the complexities of the global supply chain, forge strong supplier relationships, and leverage technological innovations will be key to success. By embracing these challenges and opportunities, the aviation industry can ensure the continued safety, efficiency, and sustainability of its operations. The strategic decisions made today will not only impact the immediate availability of aircraft components but also define the industry’s resilience and adaptability in the years to come.

FAQs

- What technological advancements are shaping the future of aircraft components sourcing?

- Digital sourcing platforms, blockchain for traceability, and the development of sustainable component manufacturing are key advancements.

- How can the aviation industry adapt to future sourcing challenges?

- By staying informed about technological trends, prioritizing sustainability, and developing flexible, resilient sourcing strategies.

- What role will sustainability play in future aircraft components sourcing?

- Sustainability will become increasingly important, with a focus on eco-friendly materials, manufacturing processes, and reducing the carbon footprint of the supply chain.